Eigenschaften unserer 1000 Watt Lasermaschine

1.Stabilität und Zuverlässigkeit des Lichtwegsystems und des Steuerungssystems

2.Importierte Original-Faserlaser, hohe und stabile Funktion, Lebensdauer ist über 100000 Stunden

3. Höhere Schnittqualität und Effizienz, Schnittgeschwindigkeit beträgt bis zu 80 m / min mit Aussehen und schöner Schneide

4.German Hochleistungsreduzierer, Zahnrad und Zahnstange; Japanische Führung und Kugelumlaufspindel.

Anwendbare Industrie und Materialien von Faserlaserschneidanlage

Faserlaserschneidanlage Anwendung:

Metallzerspanung, Herstellung von elektrischen Schaltern, Luft- und Raumfahrt, Lebensmittelmaschinen, Textilmaschinen, Maschinenbau, Lokomotivenbau, Land- und Forstmaschinen, Aufzugsbau, Sonderfahrzeuge, Haushaltsgeräte, Werkzeuge, Verarbeitung, IT-Fertigung, Ölmaschinen, Lebensmittelmaschinen, Diamantwerkzeuge , Schweißen, Schweißen Ausrüstung, Metallmaterialien, Dekoration Werbung, Laser-Oberflächenbehandlung von ausländischen Verarbeitungsdienstleistungen, wie alle Arten von Maschinen verarbeitenden Industrie.

Unsere FaserlaserschneidanlageBewerbungsunterlagen:

Profi zum Schneiden von dünnen Blechen in einer Vielzahl von hochwertigen 0,5 -3 mm Kohlenstoffstahlblechen, kann auch Edelstahlplatten, Aluminiumlegierungsplatten, verzinkte Bleche, elektrolytische Platten, Siliziumstahl, Titanlegierungen, Aluminiumzinkplatten schneiden und anderes Metall.

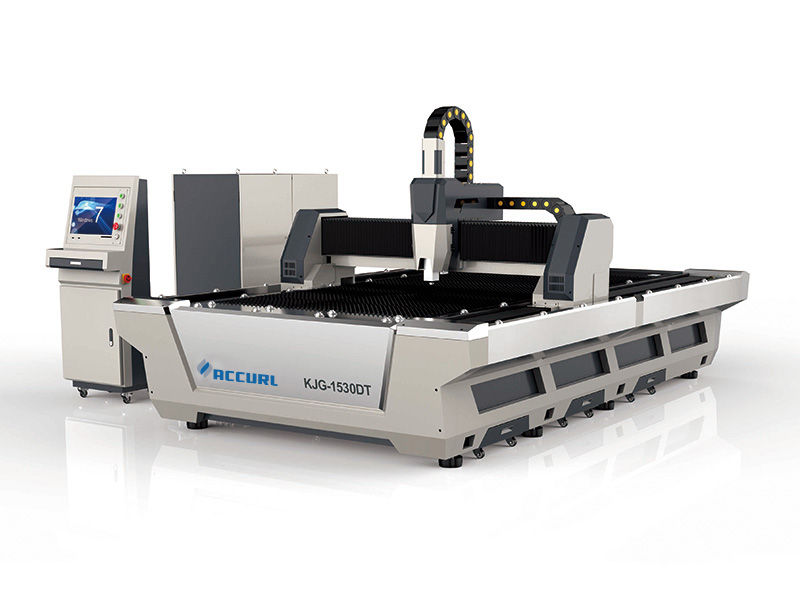

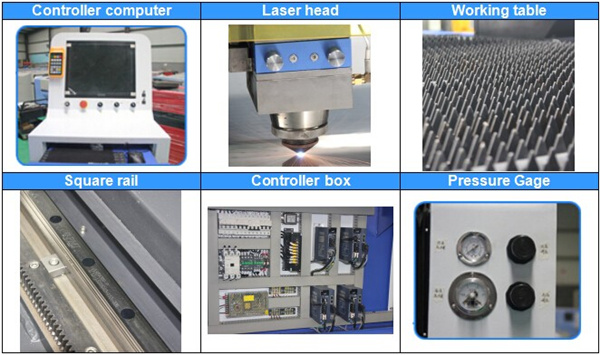

Hauptmaschinenbilder von 1kw Laserschneidmaschine

Schnelle Details

Anwendung: Laserschneiden

Artikelzustand: Neu

Lasertyp: Faserlaser

Anwendbares Material: Metall

Schnittstärke: 0-20mm

Schnittbereich: 1300 * 2500 mm

Schnittgeschwindigkeit: 25 m / min

CNC oder nicht: Ja

Kühlmodus: Wasserkühlung

Steuerungssoftware: bechoff (Cypcut)

Unterstützte Grafikformate: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Zertifizierung: CE, ISO, SGS

After-Sales-Service zur Verfügung gestellt: Ingenieure zur Verfügung, um Maschinen im Ausland zu warten

Modell: 1000 Watt Laser

Schneidmaterialien: Edelstahl Kohlenstoffstahl usw. (Metalllaserschneidmaschine)

Faserlaser-Generatortyp: Berühmte Marke Raycus (Made in China)

Faserlaser-Schneidkopf: Lasermech (aus den USA)

Motoren & Treiber: 1500W Fuji Servomotor hergestellt in Japan

Mindest. Linienbreite: ± 0,02 mm

Lebensdauer des Fasermoduls: Mehr als 100000 Stunden

Garantiezeit: Ganze Maschine für 3 Jahre (fib

Parameter unserer Faserlaser-Schneidemaschine

| Maschinen-Modell | 2500 * 1300 mm |

| Laserleistung | 300W/500W/1000W/3000W |

| Faserlaser-Generatortyp | Berühmte Marke Raycus (Made in China) |

| Laserwellenlänge | 1064nm |

Laserstrahlqualität | <0,373 mrad |

| Arbeitstisch | Sägezahn |

| Faserlaser-Schneidkopf | Lasermech (aus den USA) |

| Linse fokussieren | Lasermech made in USA |

| Lebensdauer des Fasermoduls | Mehr als 100000 Stunden |

| Motoren & Treiber | 1500W Fuji Servomotor hergestellt in Japan |

| Reduzierstück | 3 Sätze aus Deutschland |

| Führungsschienen | PMI-Marke mit hoher Genauigkeit aus Taiwan |

| Sendesystem | Typ mit zwei Zahnstangen und Ritzel |

| Regalsystem | Deutschland-Rack |

| Kettensystem | Igus made in Germany |

| Wasserkühler | Marke TEYU (S&A), CW6000 |

| Kontrollsystem | Professionelles Lasersteuerungssystem - Cypcut

|

| Positionstyp | Roter Punkt |

| Schnittstärke | ≤3mm (Edelstahl) ≤6mm (Kohlenstoffstahl) |

| Max. Leerlaufdrehzahl | 1400 mm / s |

| Schneidgeschwindigkeit | 300 mm / s |

| Positionsgenauigkeit | ± 0,05 mm / m |

| Position Geschwindigkeit | 20 m / min |

| Mindest. Linienbreite | ± 0,02 mm |

| Energieverbrauch | ≤12KW |

| Gewicht tragen | 700kg |

| Stromspannung | 380V/50HZ,3PH |

| Hilfsgas zum Schneiden | Sauerstoff, Stickstoff, Luft |

| Kompatible Software | Autocad, Coreldraw usw |

| Grafikformat | Nc |

| Arbeitsmethode | PC-Steuerung |

| Gesamtleistung Schutzklasse | IP54 |

| Maschinengewicht | Über 4000KG |

| Maschinengröße | 4800*2600*1800mm |

| Garantiezeit | Ganze Maschine für 3 Jahre (Fasermodul 2 Jahre) |

Qualitätskontrolle von 1000 Watt Laser

Qualität ist unser aufrichtiger Respekt gegenüber allen unseren Kunden und der wichtigste Faktor, um langfristige Geschäftsbeziehungen mit uns zu pflegen.

Wir achten immer mehr auf die Qualität der Laserschneidmaschine. Standard-Qualitätskontrollsystem und -team sind dafür verantwortlich, die Produktqualität in jedem Prozess mit verschiedenen Instrumenten wie Laserinterferometer und Laserleistungsmesser sicherzustellen.

Bei der mechanischen Montage werden Laserinterferometer, Laserkollimator, Messuhr und Marmorplatte verwendet; Beim Lasermontageprozess werden der Laserleistungsmesser und das optische Mikroskop verwendet.